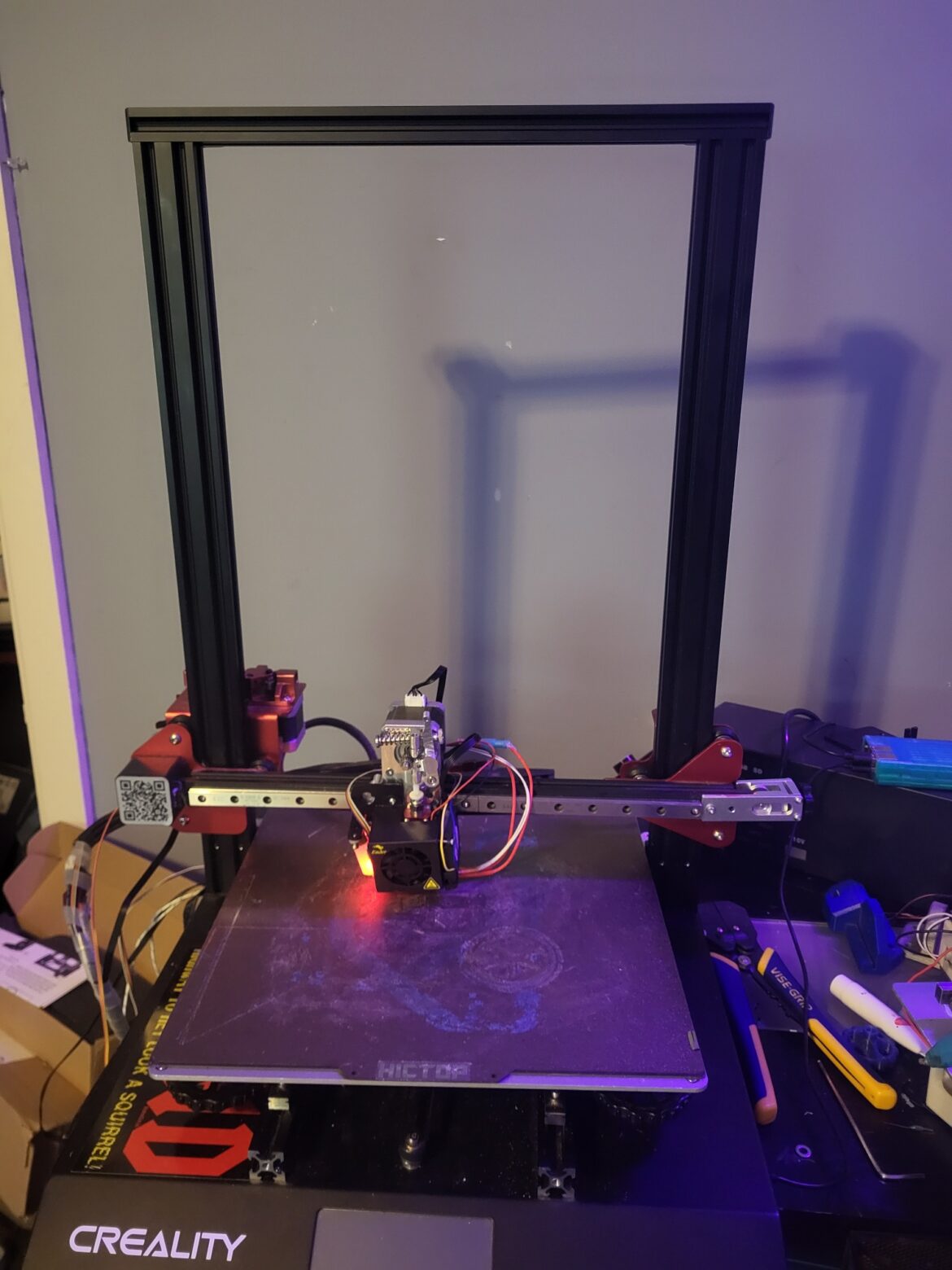

Below is my Klipper configuration I am currently working with on my CR10s Pro v1 modified system.

##############################

######## CONFIGS #############

##############################

[include mainsail.cfg]

[include KAMP_Settings.cfg]

[exclude_object]

[save_variables]

filename: variables.cfg ; variable storage file

;[include adxl345.cfg]

[include accelerometer.cfg]

############################################################

# #

# SYSTEM SETTINGS #

# #

############################################################

[mcu]

serial: /dev/serial/by-id/usb-Klipper_stm32g0b1xx_4E00410014504B5735313920-if00

#serial: /dev/serial/by-id/usb-FTDI_FT232R_USB_UART_AK06VNMQ-if00-port0

#serial: /dev/serial/by-id/usb-1a86_USB_Serial-if00-port0

#restart_method: command

[force_move]

enable_force_move: True

[virtual_sdcard]

path: /home/jessay/fozzy_data/gcodes

on_error_gcode: CANCEL_PRINT

[printer]

kinematics: cartesian

max_velocity: 300

max_accel: 3000

max_z_velocity: 5

max_z_accel: 100

#——————————-#

#—- STEPPER CURRENTS ——– #

#—– — DIGITAL SETTINGS —- #

# —————————– #

[stepper_x]

step_pin: PB3

dir_pin: !PB4

enable_pin: !PD1

microsteps: 16

rotation_distance: 40

endstop_pin: ^PC0

#endstop_pin: ^PC7

# position_endstop: See commonly edited settings at the beginning of the file

position_max: 285

homing_speed: 10

position_endstop: 0

[tmc2209 stepper_x]

uart_pin: PC11

tx_pin: PC10

uart_address: 0

run_current: 0.580

hold_current: 0.500

stealthchop_threshold: 999999

[stepper_y]

step_pin: PB10

dir_pin: PB2

enable_pin: !PB11

microsteps: 16

rotation_distance: 40

endstop_pin: ^PC1

#endstop_pin: ^PA2

# position_endstop: See commonly edited settings at the beginning of the file

position_max: 275

homing_speed: 80

position_endstop: 0

[tmc2209 stepper_y]

uart_pin: PC11

tx_pin: PC10

uart_address: 2

run_current: 0.580

hold_current: 0.500

stealthchop_threshold: 999999

[stepper_z]

step_pin: PB0

dir_pin: PC5

enable_pin: !PB1

microsteps: 16

rotation_distance: 8

#endstop_pin: ^PA7

#position_endstop: 0.5

position_max: 315

# position_endstop: See commonly edited settings at the beginning of the file

#position_max: 200

endstop_pin: probe:z_virtual_endstop

position_min: -9

homing_speed: 8

second_homing_speed: 3

homing_retract_dist: 8

[tmc2209 stepper_z]

uart_pin: PC11

tx_pin: PC10

uart_address: 1

run_current: 0.580

hold_current: 0.500

stealthchop_threshold: 999999

#—————————–#

#——- Extruder-Homing #

#——– #

#—————————–#

[extruder]

step_pin: PB13

dir_pin: PB12

enable_pin: !PB14

microsteps: 16

rotation_distance: 33.500

nozzle_diameter: 0.400

filament_diameter: 1.750

heater_pin: PC8

sensor_type: Generic 3950

sensor_pin: PA0

control: pid

pid_Kp: 21.527

pid_Ki: 1.063

pid_Kd: 108.982

min_temp: 0

max_temp: 250

[tmc2209 extruder]

uart_pin: PC11

tx_pin: PC10

uart_address: 3

run_current: 0.650

hold_current: 0.500

stealthchop_threshold: 999999

[bltouch]

sensor_pin: ^PC14

control_pin: PA1

x_offset: -46.3

y_offset: -7.1

z_offset: 0.9

speed: 10

lift_speed: 40

samples: 5

;pin_up_reports_not_triggered: True

;pin_up_touch_mode_reports_triggered: True

probe_with_touch_mode: True

# Old Sensor

#[probe]

#pin: PB4

#pin: !PD3

#deactivate_on_each_sample: False

#x_offset: -28 # as measured on the printer, the offset is actually 28mm

#y_offset: 0

#z_offset: 2.3 # this needs to be adjusted for each printer to achieve correct first layer height

#speed: 2 # very slow approach speeds are a MUST, even with a high quality capacitive probe; more so with OEM probe

#ift_speed: 1.0

#samples: 2 # this is excessive, but it satisfies my OCD tendencies

#sample_retract_dist: 9

#samples_tolerance: .4

#samples_tolerance_retries: 3

[input_shaper]

shaper_freq_x: 31.5 # stock CR-10S Pro with very well assembled and tuned mechanicals

shaper_freq_y: 34.0 # stock CR-10S Pro with very well assembled and tuned mechanicals

shaper_type: mzv

#[firmware_retraction]

#retract_length: 1.3 # Canadian Maker ToughPLA low sheen black @ 205 C, 20 mm/s

#retract_length: 1.5

#retract_speed: 50

#unretract_extra_length: 0

#unretract_speed: 25

[safe_z_home]

home_xy_position: 128, 139 # base 120×120, plus x and y offsets for bltouch to sit in the center

speed: 50

#z_hop: 27

#z_hop_speed: 5

#—————————#

#—— HEATBED/MESH ——#

#—————————#

[bed_mesh]

speed: 120

mesh_min: 0, 0

mesh_max: 300, 310

horizontal_move_z: 41 # 0.7~1.0mm is recommended

algorithm: bicubic

probe_count: 3,3

fade_start: 1

fade_end:20

fade_target: 0

mesh_pps: 2,2

bicubic_tension: 0.2

mesh_pps: 2

adaptive_margin: 0

[heater_bed]

heater_pin: PC9

sensor_type: EPCOS 100K B57560G104F

sensor_pin: PC4

control: pid

pid_Kp: 22.2

pid_Ki: 1.08

pid_Kd: 114

min_temp: 0

max_temp: 130

[bed_screws]

screw1: 25,30 # exact screw location based on the X&Y endstops defined above

screw2: 275,30 # exact screw location based on the X&Y endstops defined above

screw3: 275,270 # exact screw location based on the X&Y endstops defined above

screw4: 25,270 # exact screw location based on the X&Y endstops defined above

horizontal_move_z: 5.0

probe_height: 0.2 # use the Creality supplied 0.2mm feeler gauge for manual adjustment to avoid bed damage

speed: 80

probe_speed: 3.2 # can approach faster than bed mesh probing for a coarse manual screw adjustment

[filament_switch_sensor e0_sensor]

switch_pin: !PC15 #ar2

pause_on_runout: False

runout_gcode:

M600

[heater_fan nozzle_cooling_fan]

pin: PC7

[heater_fan controller_fan]

pin: PB15

heater: heater_bed

heater_temp: 45.0

[board_pins]

aliases:

# EXP1 header

EXP1_1=PB5, EXP1_3=PA9, EXP1_5=PA10, EXP1_7=PB8, EXP1_9=<GND>,

EXP1_2=PA15, EXP1_4=<RST>, EXP1_6=PB9, EXP1_8=PD6, EXP1_10=<5V>

[display]

lcd_type: emulated_st7920

spi_software_miso_pin: PD8 # status led, Virtual MISO

spi_software_mosi_pin: PD6

spi_software_sclk_pin: PB9

en_pin: PB8

encoder_pins: ^PA10, ^PA9

click_pin: ^!PA15

[output_pin beeper]

pin: PB5

#[output_pin stepper_xy_current]

#pin: PL3

#pwm: True

#scale: 2.0

#cycle_time: .000030

#hardware_pwm: True

#static_value: 1.3

#[output_pin stepper_z_current]

#pin: PL4

#pwm: True

#scale: 2.0

#cycle_time: .000030

#hardware_pwm: True

#static_value: 1.3

#[output_pin stepper_e_current]

#pin: PL5

#pwm: True

#scale: 2.0

#cycle_time: .000030

#hardware_pwm: True

#static_value: 1.25

#[static_digital_output stepper_config]

#pins:

# PG1, PG0,

# PK7, PG2,

# PK6, PK5,

# PK3, PK4

#[static_digital_output yellow_led]

#pins: !PB7

[gcode_macro START_PRINT]

gcode:

; Get first-layer bed-temp from slicer

{% set BED_TEMP = params.BED_TEMP|default(70)|float %}

; Get first-layer extruder-temp from slicer

{% set EXTRUDER_TEMP = params.EXTRUDER_TEMP|default(170)|float %}

G90 ; use absolute coordinates

M83 ; extruder relative mode

M104 S170 ; set extruder temp for bed leveling

M140 S{BED_TEMP} ; set bed temp

M109 S170 ; wait for bed leveling temp

M190 S{BED_TEMP} ; wait for bed temp

G28 ; home all axis

; mesh bed

BED_MESH_CALIBRATE PROFILE=adaptive ADAPTIVE=1

M104 S{EXTRUDER_TEMP}; set extruder temp

G0 Z50 F240

G0 X2 Y10 F3000

Smart_Park

M109 S{EXTRUDER_TEMP} ; wait for extruder temp

LINE_PURGE ; purge nozzle

[gcode_macro END_PRINT]

gcode:

G91 ; Relative positioning

G1 E-3 F1800 ; Retract

G1 F3000 Z3 ; Move up

G90 ; Absolute pos.

G1 X235 Y185; present print

# Turn off bed, extruder, and fan

M140 S0

M104 S0

M106 S0

SAVE_IF_SET ; SAVE_CONFIG if a mesh was probed in START_PRINT

M84 ; Disable steppers

#*# <———————- SAVE_CONFIG ———————->

#*# DO NOT EDIT THIS BLOCK OR BELOW. The contents are auto-generated.

#*#

#*# [probe]

#*#

#*# [extruder]

#*# control = pid

#*# pid_kp = 28.113

#*# pid_ki = 1.511

#*# pid_kd = 130.724

Synopsis

Yoshino Somei is the granddaughter of the head of a major yakuza clan in the Kansai region. When her grandfather arranges her marriage to Kirishima Miyama, the grandson of a powerful rival clan leader in Kanto, Yoshino is compelled to move to Tokyo. Though Kirishima appears warm and welcoming, almost making her forget his yakuza ties, a pivotal event will soon expose his true nature.

List of mods

List of mods

- X Axis Linear Rail

- Y Axis Dual Linear Rails

- 4 linear rail carriage custom design for the bed

- Redid the wiring for easy connection and disconnection

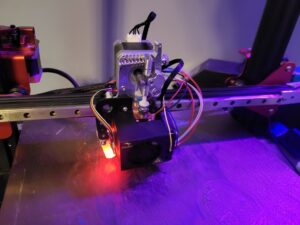

- SKR Mini E3V3

- Direct Drive

- BLTOUCH

- and more!